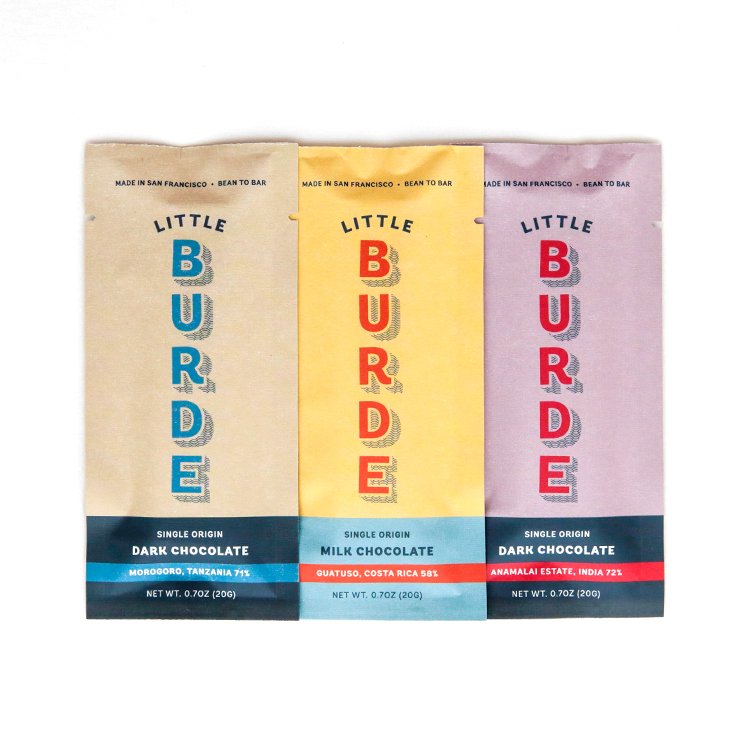

Each Little Burde Bar is made from beans ethically and directly sourced by Meridian Cocoa. A single batch makes as little as 100 and up to 250 bars. With so many changing variables, each batch is unique.

My current batch maximum is about 8 kilograms of un-roasted beans which, after sorting the bad beans from the good ones, yields about 7 kilograms of delicious chocolate. Typically, with a good batch where all goes right, there will be about 200 bars to share with you all. Changing variables such as adding a couple of seconds to the bean’s roasting time can change the flavor of the chocolate. This makes every Little Burde batch of chocolate unique and each bar a rare taste of that batch. That’s why we record each batch number at the back of the bars.

Here is a quick summary of the basic steps of making chocolate:.

SORTING

We hand sort all of the beans, removing any that will not roast evenly or may upset the taste. Sorting is a skill developed with time and experience.

ROASTING

The beans are divided into 1 kilogram batches and roasted in a small drum roaster. Each batch requires about 40 minutes to roast and cool.

CRACKING

The roasted beans are then cracked with a hand operated Crackenstien.

WINNOWING

Winnowing refers to the process of removing the husks from the cracked beans, leaving the nib. The nib is the chocolate or the part that we eat. This is done in Cocaotown small batch winnower hooked up the fancy little store bought shop vac.

PRE GRINDING

The nibs are then pushed through a pre grinder

MELANGING & CONCHING

Melange is a french word literally meaning mixture. A conche is a scraping mixer that evenly distributes cocoa butter within chocolate.

Melanging and conching are two steps that happen simultaneously at Little Burde because we are not operating in a large factory. The pre ground chocolate is paste like in its viscosity and is poured into smaller stone grinders. The chocolate then mélanges or mixes for several hours until finally the only other ingredient, organic evaporated cane sugar, is added (our dark milk bars get organic Humbolt Creamery milk and cocoa butter added). The chocolate continues to mélange for another 24-30 hours depending on the size of the batch. Once this is complete the liquid chocolate is poured out to harden at room temperature.

AGING

Little Burde chocolate is typically only aged about 1 week to 1 month, just long enough to let the flavors settle.

TEMPERING

The final step in chocolate making is tempering. A tempering machine heats and cools the chocolate in a specific sequence to very exact temperatures in order to make the chocolate shelf stable and is what gives it the sheen and the snap we are accustomed to. Essentially, tempering allows the chocolate to melt in your mouth and not in your hand.

MOLDING

The tempered chocolate is then poured into the little 20 gram molds and set aside to harden before they are delicately wrapped and delivered to our stockists.

To learn how you can get your hand on a LBB simply click on the want some below or check our stockists link.